Research & Development

Ever since the early 1990s, Polarttech has been a pioneer in the field of developing and implementing existing and new production technologies. This has made us a leading company in the polyurethane industry, now and for the future.

Polarttech’s hunger for process and product innovation started with the casting and machining of polyurethane in the early 1990s. This was followed by three years of extensive testing and development of this extremely versatile and specialist product.

Proces innovation

Polarttech mixes and vacuums its polyurethane systems in a unique way. Ongoing research and development has enabled us to add various additives to polyurethane, such as: UV protectors, MoS2, steel and aluminum powders, PTFE, glass, graphite and chalk. This enables a great variety in materials – and properties.

Product innovation

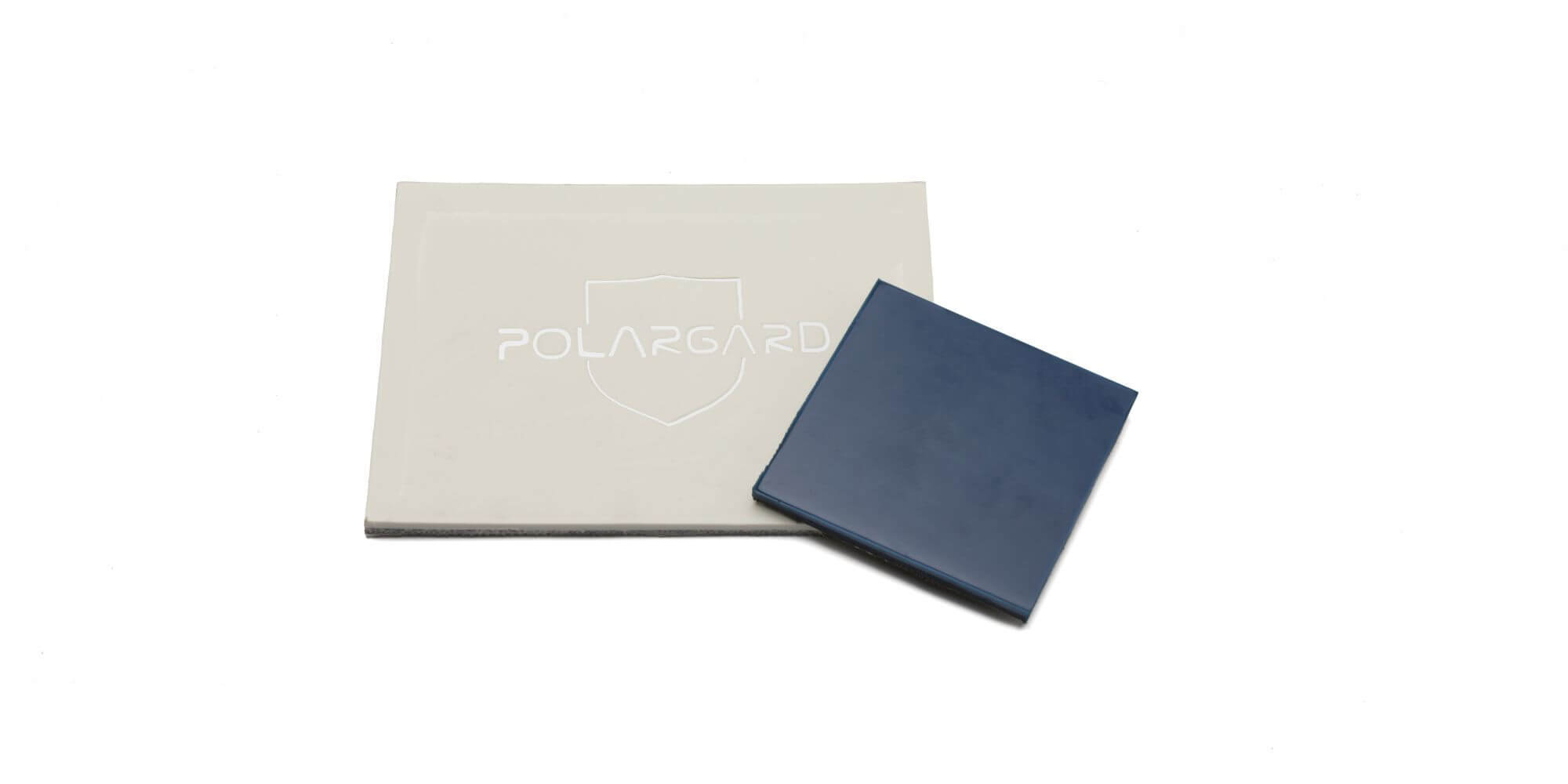

Besides optimising its processes, Polarttech is also continuously in search of new products. For example, in 2012 we had synthetic backing materials made and we also performed extensive tests for casting-on polyurethane. This resulted in a new and unique product which we call Polargard®. This is a hard-wearing polyurethane sheeting material with a backing with an open structure, enabling the Polargard® sheeting to be bonded to sheet steel products like vibrating hoppers and chutes.

Sustainable polyurethane materials

Sustainability is important in our vision for the future. We are constantly investigating the possibilities of producing "greener" products.